Laboratory

The Design Studio Laboratory is located in the basement of E-Block. There are lockers located outside the laboratory. Each team will be assigned a locker space which you will use until the end of the course series (Mid June). Please note that anything left in the lockers for the summer will be disposed off. To gain access to the laboratory every student should read Laboratory Rules, sign it and return it to your Lab Engineer, Mustafa Mürcan. Mr. Mürcan will be available in his office at the Design Studio Laboratory every Tuesday and Friday between 14:00 and 16:00.

Digital Signal Generators and Oscilloscopes: 5 sets of Signal Generator and Digital Oscilloscope Pairs are located in the Design Lab for your use. You should make every effort to keep them functional by remembering your training, carefully checking the manuals and simply being careful and considerate while using them. Please take good care of all these equipment as it takes considerable time, effort, and budget to replace them.

Power Supplies: There are also a set of power supplies for the use of every team till the end of their projects. Contact your Lab Engineer, Mustafa Mürcan, to have access to them.

Other Resources

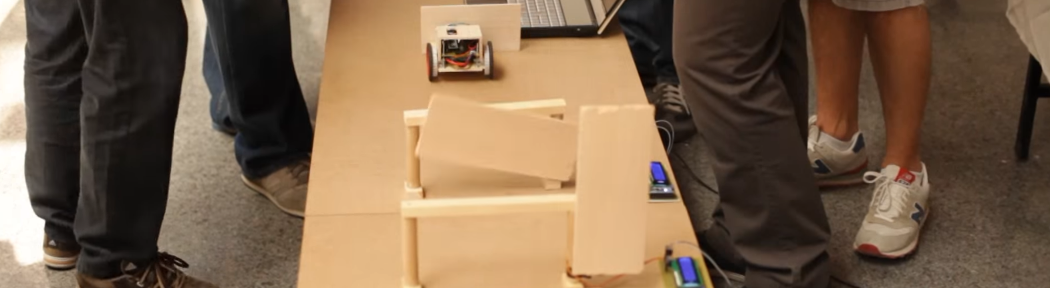

3D Printers: There are (currently three) “Ultimaker 2” model 3D Printers dedicated to EE493-494 course, located in the A-Block at room EA204. Please check the web site of the company, try to watch tutorial videos, download and read the manual. Also download the “Computer Aided Manufacturing” CAM software of the printer manufacturer company called “Cura”. It works both on Linux and Windows and is an excellent software where you can transform you parts filed from a CAD program (such as the .stl format from SolidWorks or Google Sketch-Up) to the Printer’s native G-Code Language and simulate the printing process for different parameter settings.

However, do not try to tamper with the default settings before you get enough information and some experience with the results. We are mainly using the PLA plastic material which produced less odor while printing. The printers are under the responsibility of Mr. Mustafa Mürcan. He will regulate the use of the systems as well as give you advice and directions.

Machine Shop: There is a Machine Shop located in the basement of C-Block. Students taking the EE493-494 course series can make use of this machine shop, by coordinating the technician Mr. Kemal Oncu. Please note that Mr. Oncu is responsible for all the mechanical jobs of all EE buildings and is usually very busy. You need to fit in to his schedule, not the other way around.

Procedure to use Machine Shop and 3-D printers

- You will download and fill in the Machine Shop and 3D Printing Request Form together with a sketch of solid drawing of the part that you intend to make. The overall drawing may have multiple sub-drawings and should make the part clear to a inspector, (Note: As EE493 Students, you do not need the Department Head signature on the forms but only your coordinator signature)

- You will discuss the form contents and the part to be made with your design studio coordinator who will approve your form or request some revisions,

- For the non-3D Printed work (metal/wood working, cutting etc., it may be beneficial to discuss the part with Kemal Oncu, or for 3D Printing with Mesut Ozer before getting the approval of your Coordinator.

- Your work order will be handed to Kemal Oncu or Mesut Ozer. They may direct you or suggest revisions which you will have to comply with. You will personally supervise the process for 3D Printing as things may not always go as expected. In this case, Mesut may suggest corrections and improvements.

- Each process has its time requirements. Therefore, try to keep the work as simple as possible. 3D Printing software Cura gives you an estimate of printing time and the amount of material used. You will have to be there during that period of time.

Production Costs: In order to follow our general Company-Product scenario, marginal production costs are determined to use the production facilities. 3D Printing does not have too much labor cost, so it is all about material costs and printer time (which may be quite long).

The non-negotiable costs are as follows (to be updated every year):

- 3D Printing: 2 TL/ gram of material used (Estimated by the printer and the Cura software). You should get a “simulated receipt” from the responsible technician and hand this to your design studio coordinator who will keep track of your progress.

- Machining in our Machine Shop. 2TL / 5TL / 10 TL, estimated by Kemal Oncu depending on labor and materials required. You should get a “simulated receipt” from the responsible technician and hand this to your design studio coordinator who will keep track of your progress.